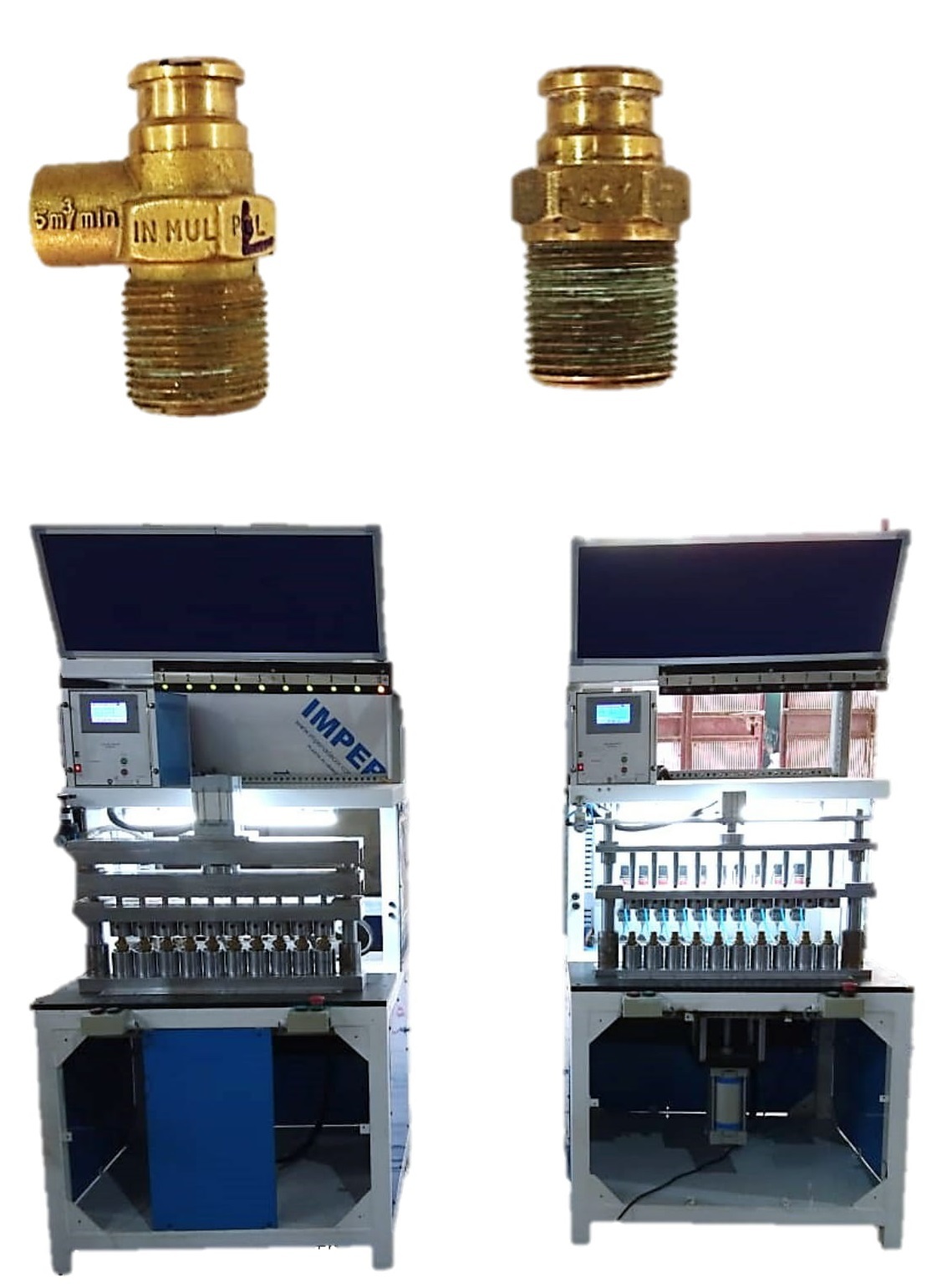

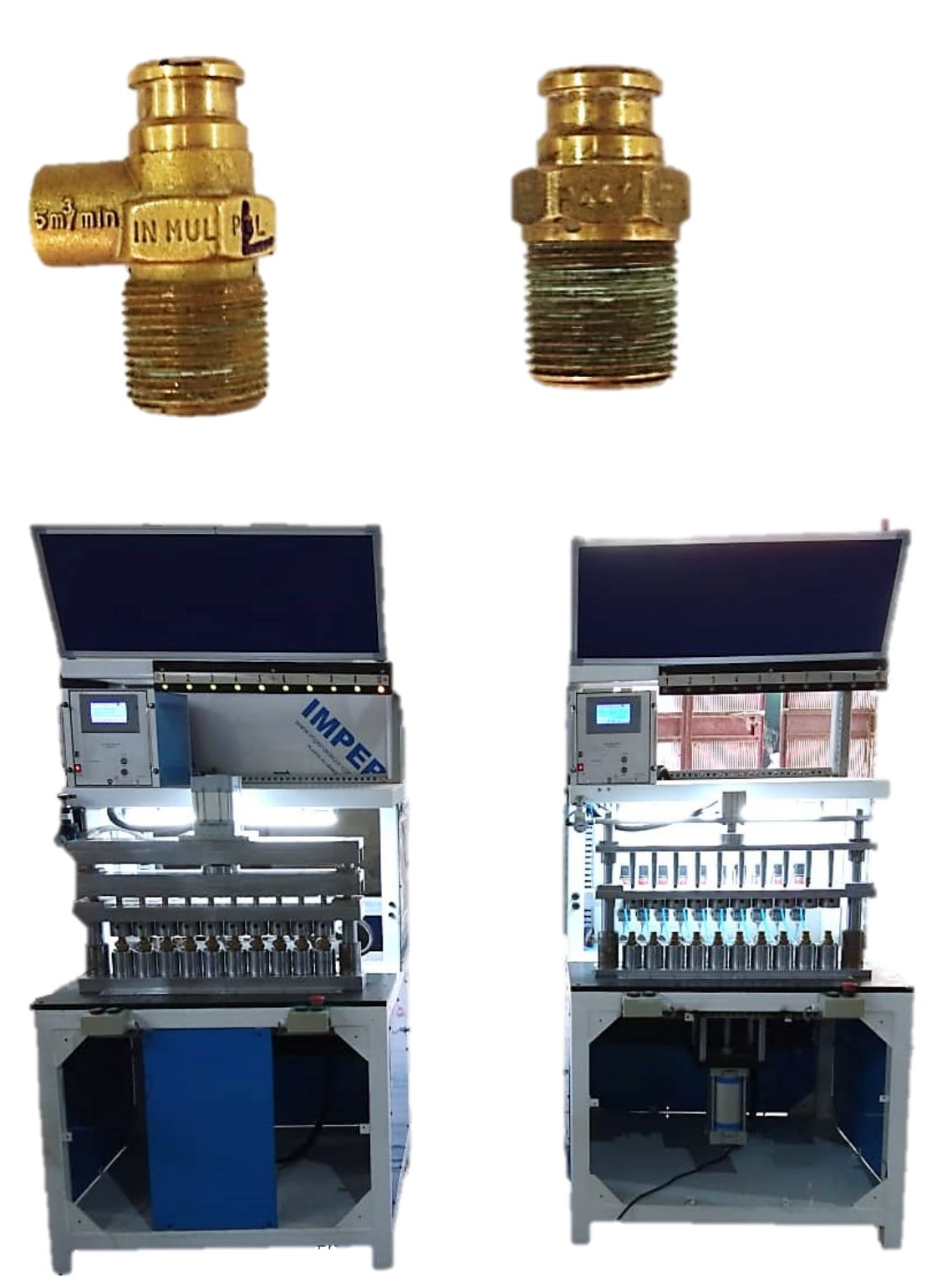

Valve Leakage Testing Machine

Valve Leakage Testing Machine Specification

- Weight

- 100-500 Kilograms (kg)

- Power Supply

- 220V

- Color

- Sliver

- Gas Pressure

- 0.2 Bar

- Power

- 200 Volt (v)

- Voltage

- 240 Volt (v)

- Type

- Other

- Use

- Commercial

- Operating Voltage

- 220 Volt (V)

- Operating Mode

- Auto / Manual

Valve Leakage Testing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Days

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, Central America, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 : 2015

About Valve Leakage Testing Machine

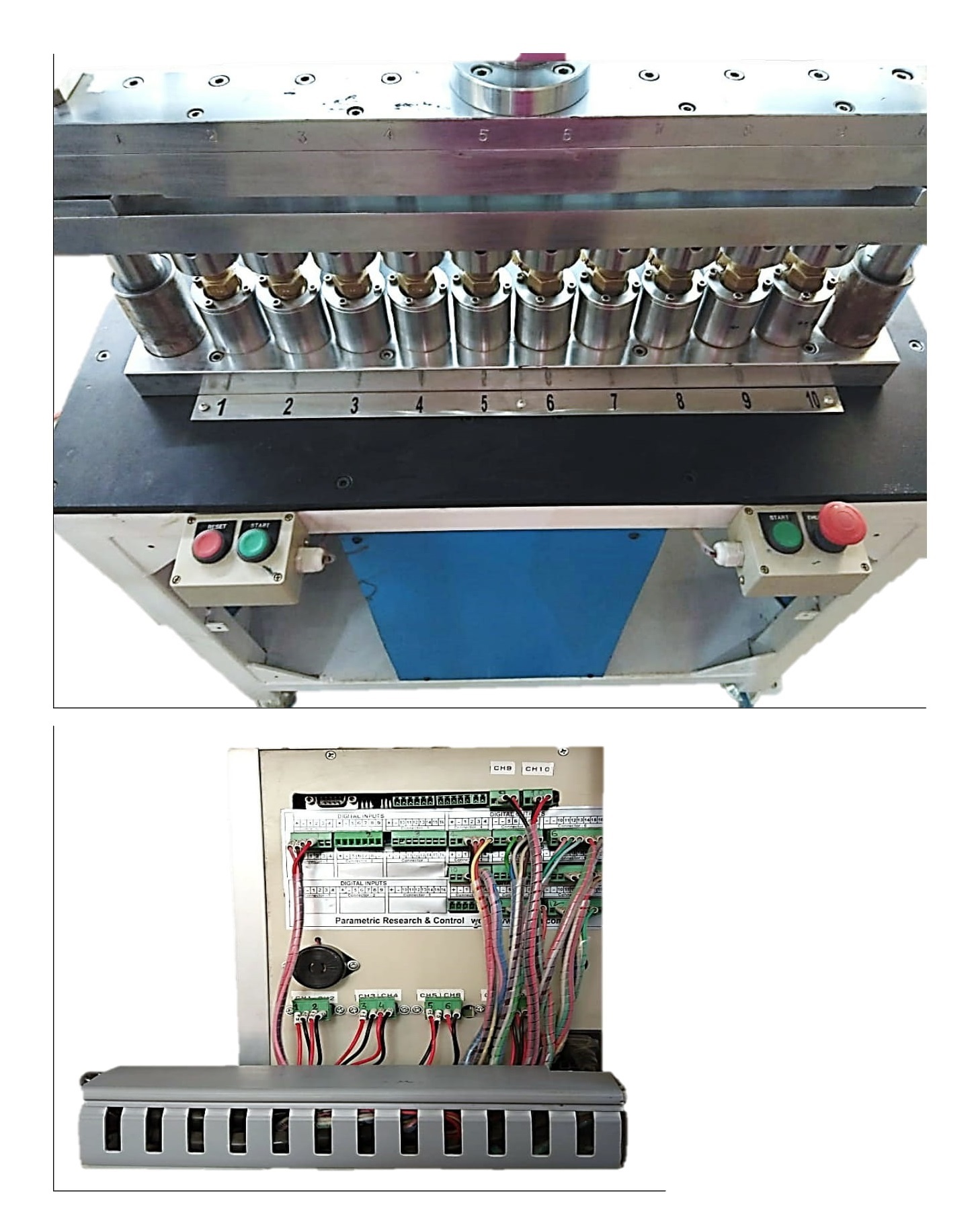

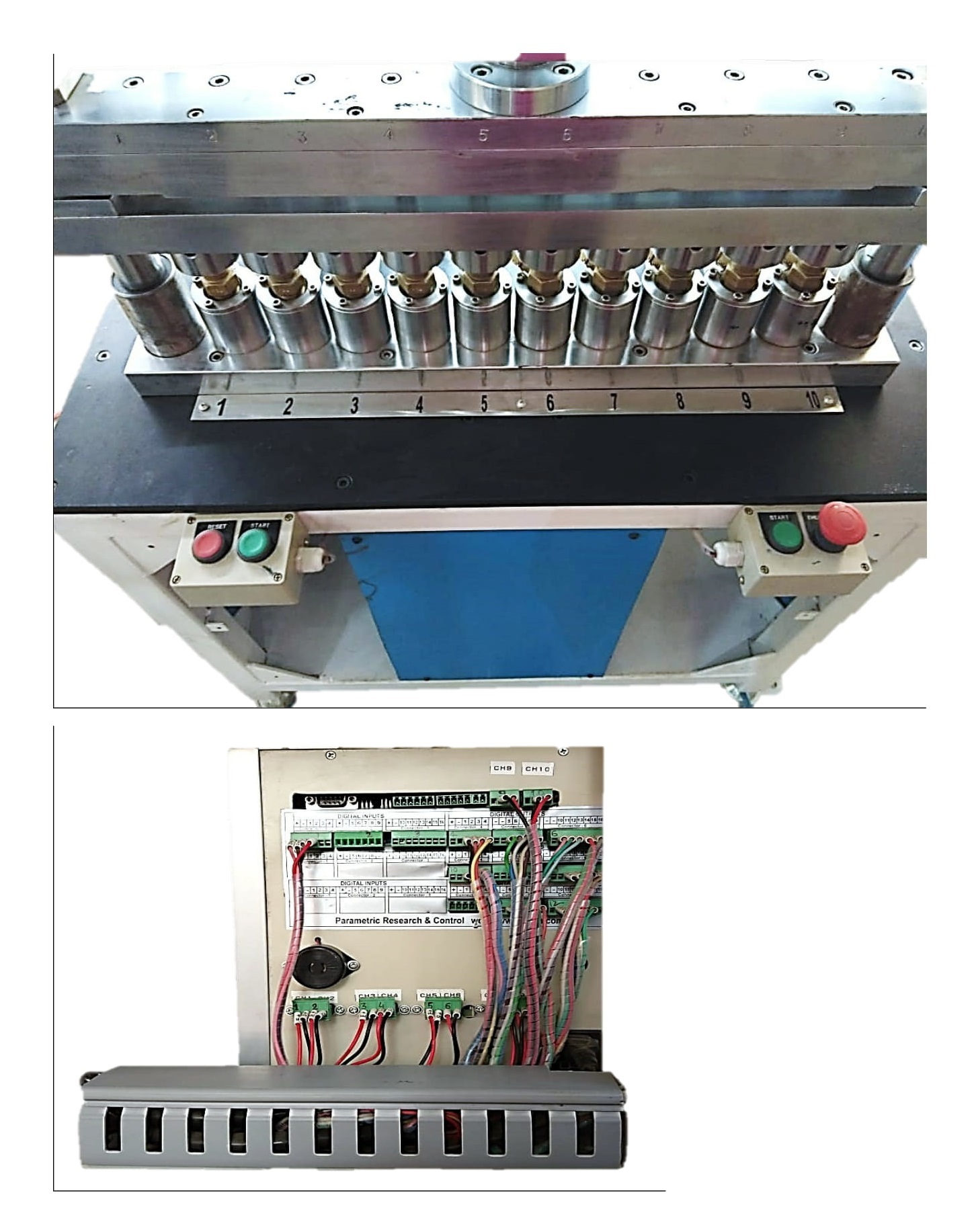

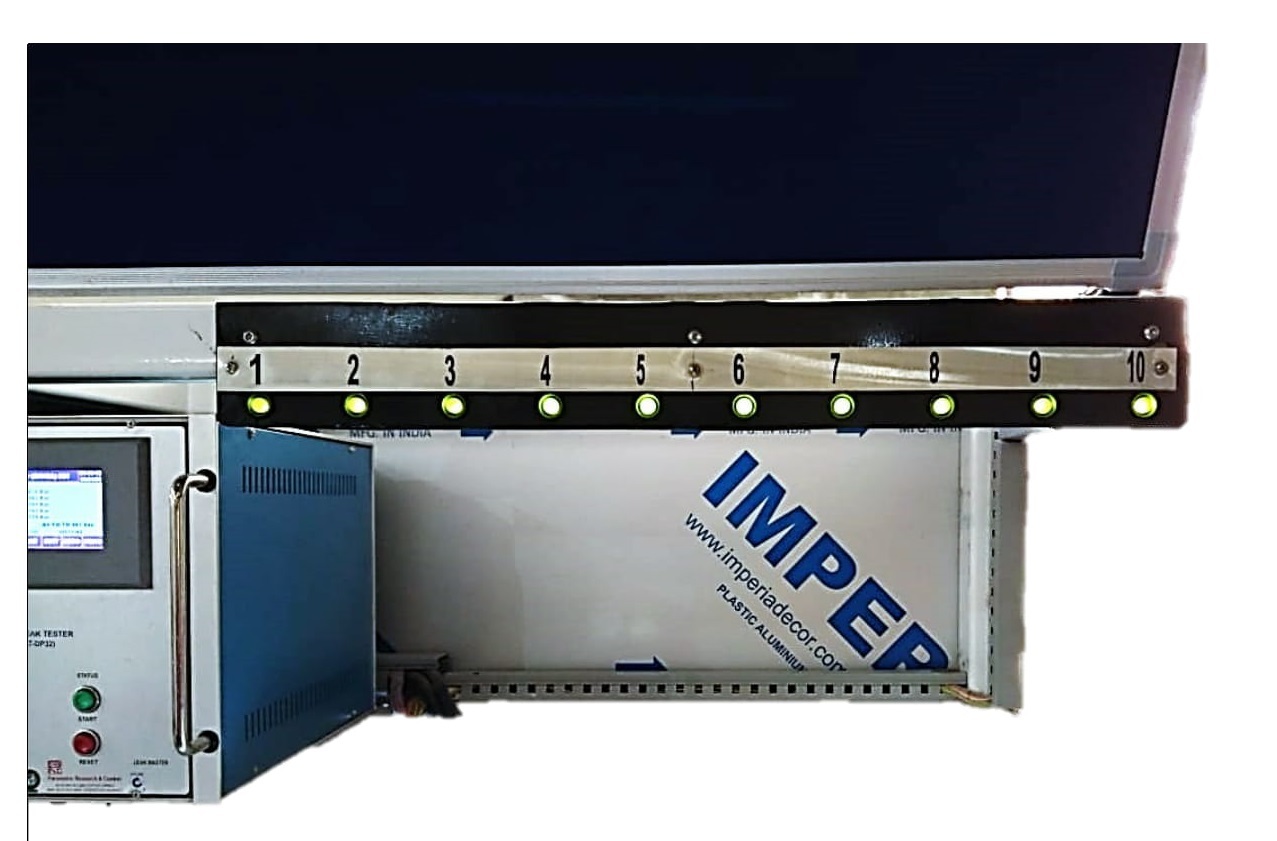

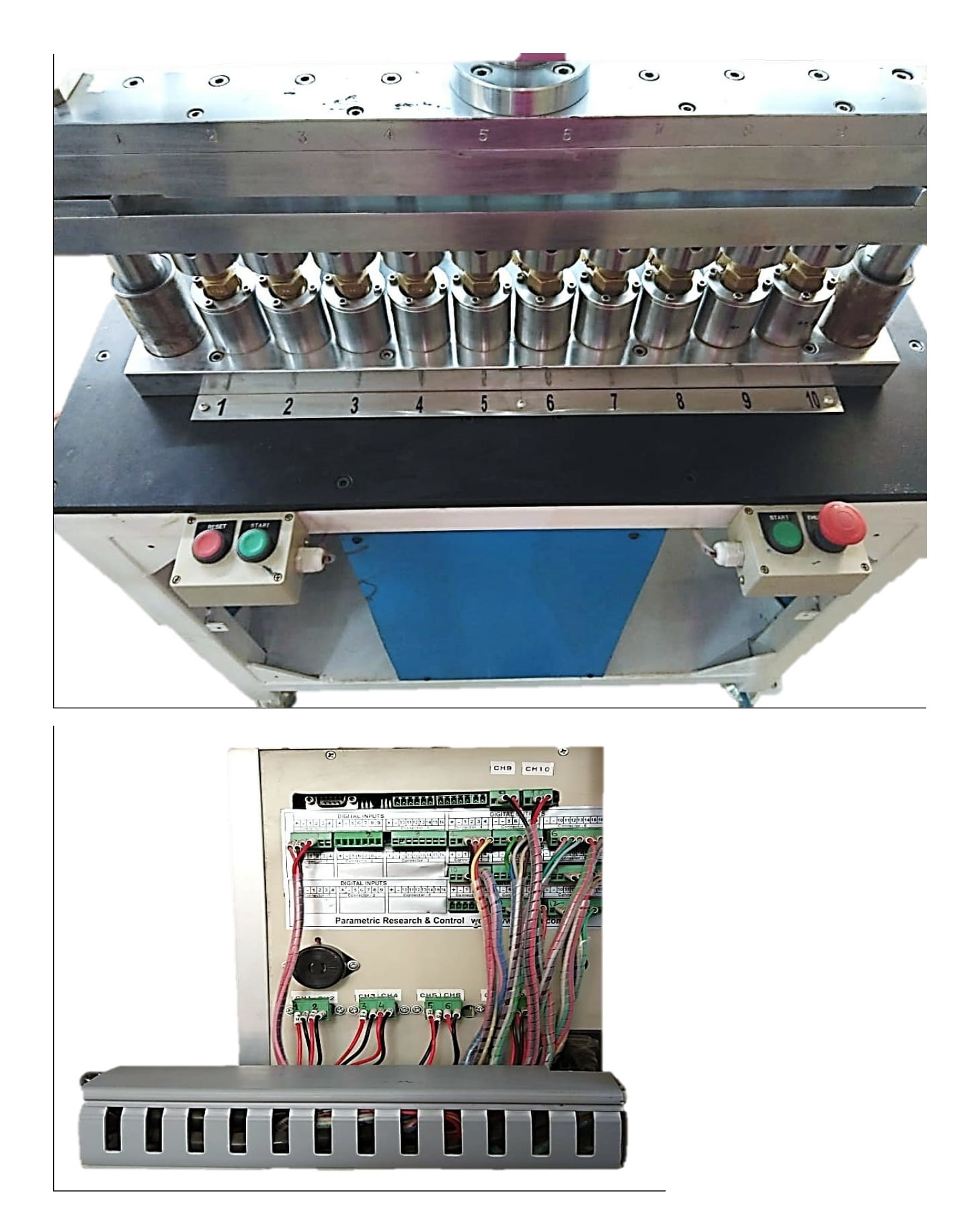

Parametric Research & Control offers its most advanced Valve Leakage testing Machine designed for any type of automotive components. The leak test is performed using a test pressure of 25 bar and a maximum pressure drop of 4 bar is permissible within 55 seconds. OK and NG results are displayed on an operator HMI. A tamp printer is included to mark the tested valve block if all four test have passed. In the event that a test fails, the part is locked into the fixture and the operator is required to take action.The machine is based on differential pressure principle.

Power Supply Mains 220 V AC, 50 Hz, +/- 10%Internal 24 V DC-4.5 amps5 V DC-3 amps12 V DC-1 amps

Efficient Commercial Valve Leakage Testing

This machine guarantees precision in leakage testing for various commercial valves. Users benefit from ease of operation and high sensitivity due to its adjustable automatic and manual modes. With its sturdy build and efficient power management, it is suitable for enduring industrial workflows, supporting both reliability and safety in critical processes.

Versatile Performance and Utility

The Valve Leakage Testing Machine offers adaptability across different voltage requirements and flexible operating settings. Designed for heightened efficiency and minimal maintenance, it streamlines testing and helps facilities maintain high standards in valve performance. Its silver finish and ergonomic design make it ideal for modern commercial environments.

FAQs of Valve Leakage Testing Machine:

Q: How does the Valve Leakage Testing Machine operate?

A: The machine can be run in both auto and manual modes, providing users with the flexibility to choose their preferred method. Operating with a 220V power supply and 0.2 bar gas pressure, it precisely identifies leaks in commercial valves, enhancing quality control.Q: What types of valves can this testing machine be used for?

A: This machine is suitable for a wide range of commercial valves commonly found in industrial sectors. Its adjustable operating parameters make it compatible with various valve sizes and specifications.Q: When should I use a valve leakage testing machine in my operations?

A: It is recommended to use the testing machine whenever valves require maintenance checks, quality assurance verification, or before installation to ensure their integrity and prevent leakage failures.Q: Where is this valve leakage testing machine manufactured and supplied from?

A: The machine is manufactured, exported, and supplied by trusted companies based in India known for their expertise in industrial machinery.Q: What is the process involved in testing valve leakage with this machine?

A: The process involves securing the valve, setting the appropriate gas pressure to 0.2 bar, and operating the machine in auto or manual mode. The device then detects any leaks, providing accurate results to guide maintenance or replacement decisions.Q: How can this machine benefit my business operations?

A: By ensuring valves are leak-free, the machine helps lower the risk of process interruptions, improves operational safety, and reduces costs associated with undetected valve leakage. Its robust design also ensures long-term usability and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Leakage Testing Machines Category

LCD Type Batch Weighing System

Price 57500 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 190*130*90 Millimeter (mm)

Material : Iron and Aluminium

Voltage : 220V AC Watt (w)

Power : 220V Watt (w)

Light Testing Panel

Price 55000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 173 x 21 Millimeter (mm)

Material : Stainless Steel

Voltage : 110 Volt (v)

Power : 220 Volt (v)

Horn Tester

Price 135000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 173 x 21 Millimeter (mm)

Material : Stainless Steel

Voltage : 110 Volt (v)

Power : 200 Watt (w)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free