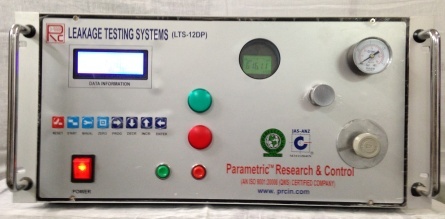

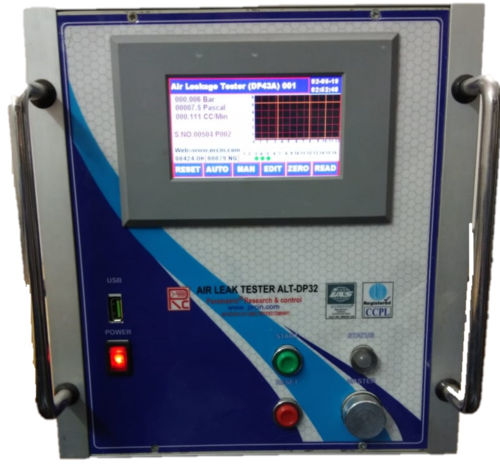

Leakage Testing System Differential Pressure

Product Details:

- Voltage 220 Volt (v)

- Product Type Leakage Testing System

- Dimension (L*W*H) 103 x 80 x 200 Millimeter (mm)

- Weight 10-100 Kilograms (kg)

- Material Aluminium

- Power 230 V, 50 Hz Watt (w)

- Click to View more

Leakage Testing System Differential Pressure Price And Quantity

- 225000 INR/Unit

- 1 Number

Leakage Testing System Differential Pressure Product Specifications

- Leakage Testing System

- 10-100 Kilograms (kg)

- 220 Volt (v)

- 103 x 80 x 200 Millimeter (mm)

- 230 V, 50 Hz Watt (w)

- Aluminium

Leakage Testing System Differential Pressure Trade Information

- Telegraphic Transfer (T/T)

- 1000 Number Per Month

- 1 Days

- Western Europe Central America Eastern Europe Middle East South America Asia North America Australia Africa

- All India

Product Description

PRC has got expertise in developing & manufacturing Differential Pressure type Leakage Testing system which is one of the fastest methods of leakage testing, Differential pressure testing is well suited for many applications. Differential Pressure leakage testing involves measuring the drop in pressure inside the component over time as a result of escaping material. However, in a differential pressure test, the change in pressure is measured inside the part compared to the pressure inside a control volume charged to the same pressure as the component.

The differential pressure leakage test, is easy to set up, but can prove much more sensitive in certain leakage detection applications. The sensitivity of the transducer is not related to the actual pressure in absolute or gauge pressure terms, but to the sensitivity of the differential pressure transducer at the test pressure.

PRC make DP Leakage Testing systems are unparalleled and well suited to differential pressure test requirements in the automotive, engineering & pharmaceutical sectors.

Salient Features:

- Panel with 24-bit A/D converter for fast processing

- High-resolution test results

- Fully integrated electronics and pneumatic

- Integrated self test feature

- Automatic environmental drift compensation

- Computer connectivity through RS 232

- Pressure resolution to 0.004%

- Sturdy & Long lasting pneumatic valves

- Easy calibration

- High quality Differential Pressure Transducer to measure the difference between the test part and a Master volume.

- High quality Absolute Pressure Transducer to check test pressures and displays pressure relative to atmosphere (gauge pressure).

- Selectable digital Inputs & Outputs

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free