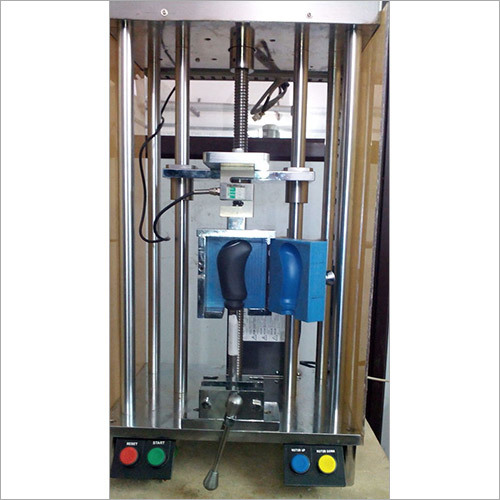

Leakage Testing Machine for Flange

Leakage Testing Machine for Flange Specification

- Color

- Sliver

- Weight

- 50-100 Kilograms (kg)

- Dimension (L*W*H)

- 120 x 65 x 220 Millimeter (mm)

- Material

- Aluminium

- Power

- 200 Watt (w)

- Voltage

- 380 Volt (v)

- Product Type

- Leakage Testing Machine for Flange

Leakage Testing Machine for Flange Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Units, , Per Month

- Delivery Time

- 1 Days

- Main Export Market(s)

- South America, Western Europe, Australia, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Leakage Testing Machine for Flange

PRC has again achieved another milestone in designing developing and manufacturing an intelligent version of leakage testing machine for flange This machine is Water dip type suitable for Capacity of 12 Bar with Testing range of 01 Bar to 12bar It is equipped with Curtain sensor for safety photo electric sensor for part presence It has got Electronic Controller with 20X4 LCD display with backlight for display parameters 16 inputs and 16 potential free relay output 8 keys key pad for parameter setting Audio visual alarm

Special feature

Auto manual operation All testing parameter to be changed by user as per requirement ie Clamping time Pressure fill time Testing time Stamping time Loading unloading Manual Auto Marking It has got Well fabricated structure with guarding sections The base plate will be machined and zinc plated to prevent rusting Structure will be duly painted where ever required and leveling pads will be provided for 110mm height adjustments This is very much user friendly operation and audio visual alarm User can run this machine without any problem for non stop performance

Features

- Highly accurate dependable

- Quick leak detection

- Multichannel operation

- Smart pneumatic electronic circuits

- Easy calibration through Leak Masters

- PC Interface through RS 232 C

- Pressure Decay leak measurements

- Strain gauge based pressure transducers transmitters

- Theory of working

The original dryair method is pressure decay in which the test part is pressurized and then isolated from the pressure source Because air moves from a highpressure area to a lowpressure area any decrease in pressure indicates the presence of a leak Algorithms then convert pressure changes into an approximation of the leak rate

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Leakage Testing Machines Category

Key Code Reader

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Product Type : Key Code Reader

Voltage : 220 Volt (v)

Power : 200 Watt (w)

MV Body Leakage Testing

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : MV Body Leakage Testing

Motor Performance & Leakage Tester

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Aluminium

Voltage : 380 Volt (v)

Power : 220 Volt (v)

Pull Force Testing Machine

Price 120000 INR / Unit

Minimum Order Quantity : 1 , , Number

Material : Aluminium

Voltage : 380 Volt (v)

Power : 220 Watt (w)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free